11 Legal Cheats Car Makers Get Away With Across The Pond

It is estimated that 80% of consumers would buy a car based on its fuel efficiency, but determining a vehicle’s efficiency can be a lot harder than initially thought.

In the US, vehicle manufacturers must test their own vehicles under controlled conditions in a laboratory using a standardized test procedure specified by federal law. The EPA then checks the results against their own test results in order to make a comparison.

In Europe however, things are very different. The test procedure known as the New European Driving Cycle (the test that defines the “official” mpg and CO2 figures) is outdated and considered no longer fit for purpose.

The test has not been updated since 1979 and therefore does not account for modern engine technology such as hybrid power, start / stop technology etc – it therefore does a poor job in reflecting real-world driving conditions.

We look at 8 reasons why this is happening.

Featured photo credit: Deals on vans by Brinn Marketing

This outdated scenario creates more problems that further assists to the false fuel figures. It encourages vehicle manufacturers to take advantage of the test’s flaws by “legally” manipulate the test in order to obtain better fuel results than what would be the case in real life…very much like VW did with its defeat device.

11 Cheats Vehicle Manufacturers Get Away With In Europe

- Over Inflating Tires

Higher tire pressure considerably reduces roll resistance. As a result, the engine requires less energy (and therefore less fuel) to move the vehicle forward.

However, over inflated tires are not recommended during driving, as doing so may result in bursting tires. - Low Rolling Resistance Tires

Low rolling resistance tires are designed not to change shape during rotation. Like with over inflated tires, this reduces friction and puts less strain on the engine and consequently saves on fuel.

Although low rolling resistance tires are available for consumer use, the manufacturers do not supply them as standard. - Disconnecting Alternator

A small percentage of fuel is used in order to keep the battery topped up. It is this that keeps the battery fully charged in order to be able to start up your car.

Manufacturers will often disconnect the alternator to prevent the charging of the battery to reduce fuel consumption. - Manipulating Brake Pads

Pushing the brake pads into the calipers will reduce resistance within the wheels when rolling. This in turn saves on fuel consumption, however, it is impossible to drive a car safely under such conditions. - Special / Non Standard Lubrication

Special & careful lubrication is used to make running of parts smoother than normal, this type of lubrication is not readily available, nor does it come as standard with the car. - Removal Of Parts

Certain vehicle parts may be removed such as the passenger wing mirror and roof racks to reduce overall weight for better fuel economy. - Used Parts

Often manufacturers will fit used parts that have been “broken in” so that they can move more freely than any new part would for better fuel performance. - Auxiliary Units Turned Off

Ancillary loads such as air conditioning, head lamps, radio, sat nav, media systems etc are turned off to reduce fuel consumption for improved figures. - Fiddling The Results

Bizarrely the NEDC procedure allows carmakers to declare (use) a value 4% lower than the one measured during the test. The provision is designed to minimize the testing burden but is being abused by carmakers to declare lower test results systematically. - Rolling Road Settings

The test cycle would normally be done on a rolling test bench rather than physically drive the vehicle on the road. Inertia needs to be factored in to replicate real world driving conditions as best as possible. However, without an independent governing board in place, car manufacturers will lower the inertia value, thereby producing test results with a 4% improvement of fuel economy. - Taping Up

Small parts of the test is done on the road and to reduce aerodynamic drag, car manufacturers will tape up indentations and protrusions on the car to allow better flow of air.

Conclusion

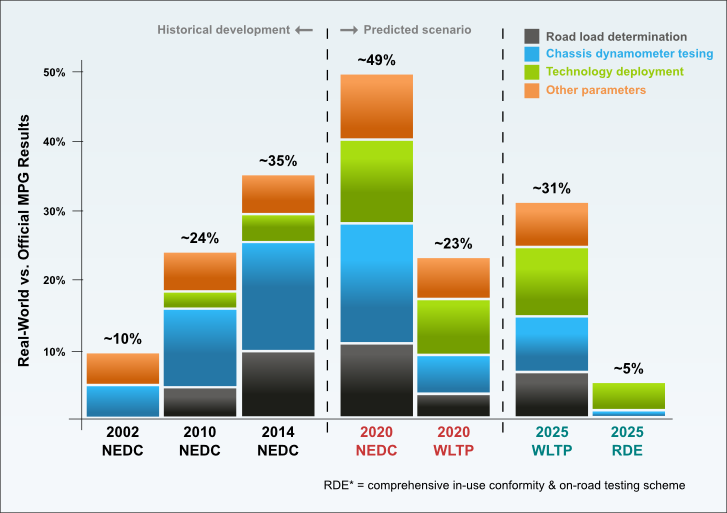

As a result to these loopholes and manufacturing cheats, the gap between test results and real world driving continues to increase rapidly year after year. It is now estimated that 98% of vehicles tested do not match their claimed mpg, consumers are spending $191 more on fuel per year and that the “official” tested mpg of cars are 40% higher than in reality (meaning your car is 40% less efficient than advertised.)

Thankfully in Europe, the NEDC will be phased out in 2017 and replaced with the WLTP which is estimated to reduce the 40% gap to 23%. Although a considerable improvement, it is only a matter of time before this gap starts to grow just like it did with the NEDC.

NEDC & WLTP Comparison Gap Increase by Transport&Environment

It seems the only way to real-world driving results would be to physically drive the vehicles on the road, or a make shift test track whereby having the vehicle pull its on weight over the tarmac, rather than simulated conditions on a test bench (roller road). This is something that the T&E and PSA Peugeot Citroën are pushing for in order to better the interests of consumers, policymakers, the environment – and ultimately for the car industry as a whole.

After all if car buyers cannot get reliable information about fuel economy, they cannot make informed choices about the cars they buy.